Discover the Versatile Use Membrane Change in Modern Electronic Devices

In the world of contemporary electronics, the application of membrane layer switches is remarkably substantial, spanning from sleek customer devices to vital medical devices. These slim, versatile interfaces not only simplify tool procedure with their tactile responsiveness however likewise considerably improve toughness by standing up to environmental dangers like wetness and dust. As sectors remain to evolve, the assimilation of membrane buttons in equipment style is critical, encouraging not just to fulfill however go beyond the rigorous demands of both capability and aesthetic charm. Discover much more concerning exactly how these components are forming the future of innovation.

Checking Out the Role of Membrane Switches Over in Customer Electronics

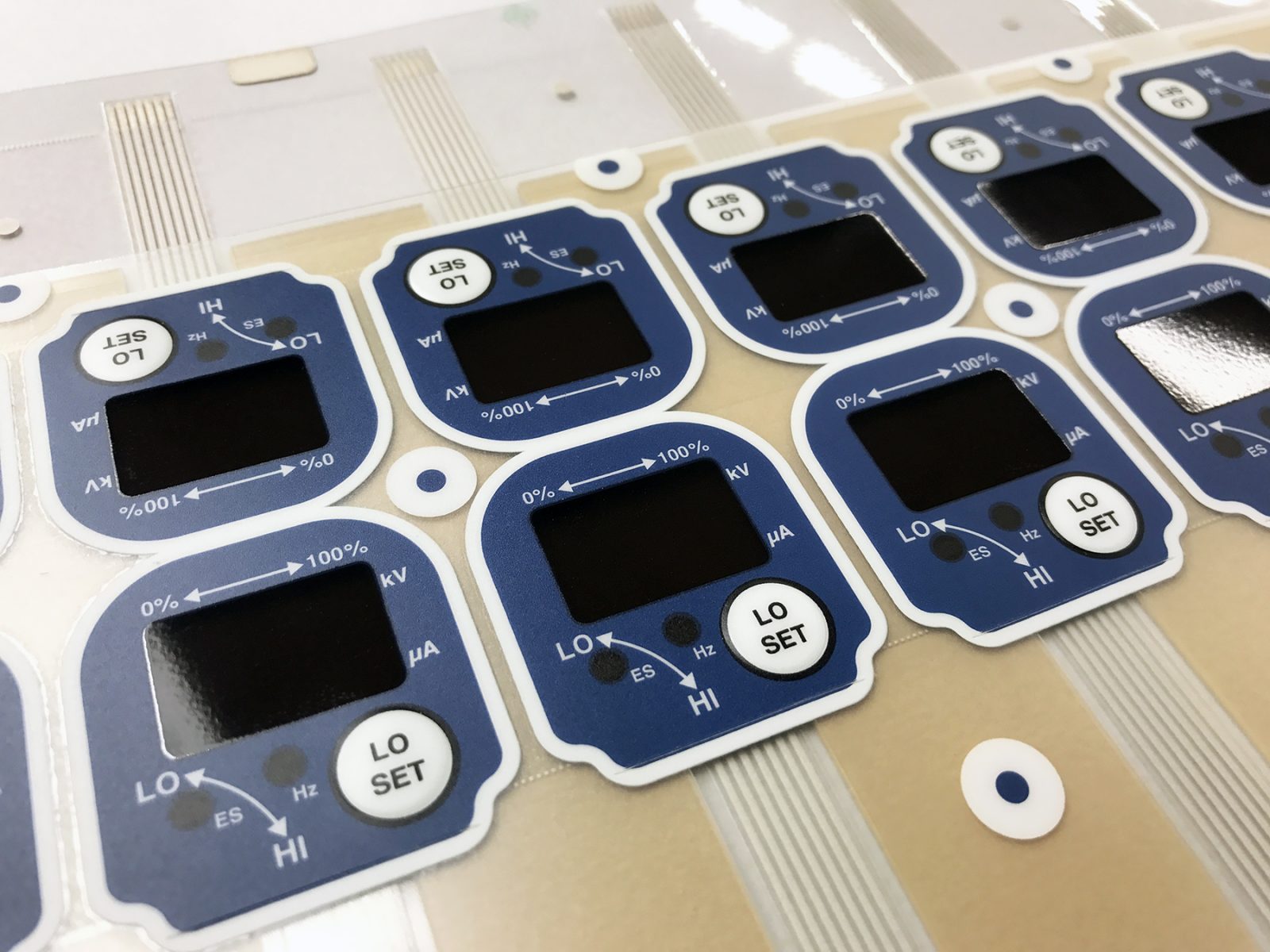

Why are membrane layer changes so widespread in consumer electronic devices? The solution hinges on their unique combination of price, reliability, and versatility. Membrane switches are economical to make, making them an attractive choice for high-volume manufacturing regular in customer electronics. Their construction, featuring a slim, adaptable layer that can easily be integrated right into numerous gadgets, enables sleek, small item styles.

Additionally, these buttons are recognized for their resilience and low maintenance. They are resistant to moisture, dust, and dirt, which enhances the durability of the digital gadgets they are utilized in. This dependability is important in daily consumer products that undertake constant usage. In addition, their convenience in layout allows personalization in appearances and functionality, catering to the specific demands of various electronic devices. From microwave ovens to remote controls, membrane switches give a practical, user-friendly interface that supports the vibrant nature of consumer electronics.

Membrane Layer Switches in Medical Instruments: Enhancing Interface

Membrane layer buttons likewise play a substantial role in the realm of medical gadgets, where they improve individual interfaces with their unique benefits. The smooth, covered surface area of membrane layer switches over permits for easy disinfection, reducing the risk of contamination and spread of pathogens.

Membrane layer buttons likewise contribute to the toughness of clinical gadgets. Their resistance to fluids and pollutants ensures that critical equipment continues to be operational in numerous professional setups, including surgical treatments where exposure to liquids is typical. This toughness, coupled with tactile feedback and inconspicuous layout, makes membrane switches an integral element in improving the efficiency and safety of medical tool user interfaces.

The Impact of Membrane Layer Changes on Industrial Devices Style

In the realm of commercial equipment style, the incorporation of membrane switches has actually marked a substantial evolution. These switches have actually transformed exactly how suppliers come close to user interface performances, supplying a blend of longevity and flexibility that is crucial in severe atmospheres. The slim account of membrane changes enables even more compact device styles, while their resistance to chemical, dust, and water impurities makes them perfect for commercial setups. This adaptability has helped with the growth of tools that is not just extra durable however likewise easier to maintain and clean, consequently minimizing downtime and functional prices.

Additionally, the customizability of membrane switches makes it possible for designers to integrate particular tactile feedback and graphical overlays that boost the customer experience and rise effectiveness. This assimilation sustains drivers in accomplishing precision control over complex equipment. The total effect is a considerable improvement in the functionality, reliability, and user-friendliness of industrial tools, straightening with the boosting demands view website for technological advancement and functional performance in modern-day markets.

Conclusion

Membrane switches have reinvented modern electronics, supplying smooth, durable, and customizable interfaces across various sectors. This technology not just meets the demanding conditions of different fields yet also substantially enhances customer experience, making membrane switches over a keystone of modern digital design.

In the world of modern-day electronics, the application of membrane buttons is incredibly considerable, extending from sleek consumer gizmos to vital medical devices.Why are membrane changes so common in consumer electronics? Membrane layer buttons are affordable to manufacture, making them an attractive option for high-volume manufacturing common in find more info customer electronic devices. From microwave stoves to remote controls, membrane buttons provide a practical, Recommended Site user-friendly interface that supports the vibrant nature of customer electronic devices.